Commercial Sewing has specialized in the marine and power sports markets with a focus on producing canvas products for Original Equipment Manufacturers, Distributors, and Dealers.

Our mission is simple. We believe ourselves to be an extension of our customer engineering and manufacturing. We value consistent communication and strive to provide our clients innovative solutions at the highest value and performance. We are consistently growing and consider ourselves to be the dominant supplier of sewn products to the OEM Power Sport and Marine markets. This level of quality and responsibility is not to be taken for granted and we strive to be flexible and fair to the needs of our customers, employees and the communities we work in.

Our staff has decades of experience in power sports and marine industries and a dedicated team of 20 engineers, project managers, and global sourcing specialists that work out of a “innovation lab” to meet and exceed customer project requirements.

Commercial Sewing is a “lean” manufacturer, capable at servicing high & low volume requirements “on-time” as well as utilizing global sourcing.

Please contact us with your project and we’ll be glad to respond in a timely fashion.

Commercial Sewing has achieved the prestigious ISO 9001:2015 certification for Quality Management, underscoring our commitment to delivering exceptional standards. This certification reflects our dedication to consistently meeting and exceeding customer expectations while maintaining rigorous quality control processes.

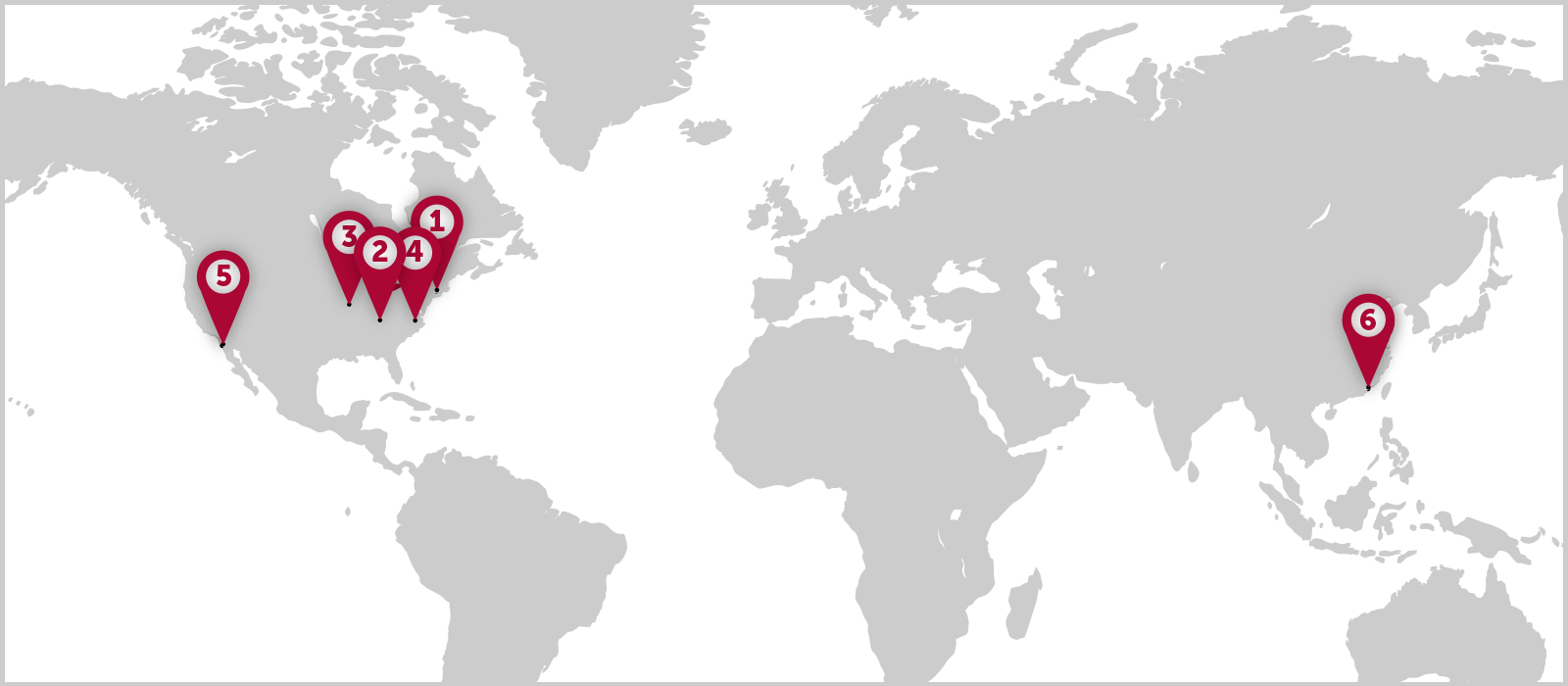

Commercial Sewing has multiple locations in the USA, Mexico and China where we design and manufacturer custom sewn products for the marine and power sports industries. The selection and vetting of our supplier and service partners is paramount to our success. We spend a considerable amount of R&D time in the quest for new fabrics, materials, service providers, and manufacturing equipment.

65 Grant Street, Torrington, CT 06790 860-482-5509 Our headquarter location encompasses a facility that is approximately 89,000 square feet. Here we employ our core engineering and management team as well as a staff of approximately 250 people to lead the design and manufacturing of all of our products.

500 RPM Drive Loudon, TN 37774 865-458-8828 Our sister company, Apex Canvas, operates out of a 30,000 square foot space that specifically focuses on sewing, assembly and delivery of marine bimini tops as well as cockpit and bow covers for our customers.

Our location in Missouri is a Central USA base that serves our ability to run fitting operations to our local clients as well as manage finished part inventory programs on behalf of our clients.

Glen Raven, North Carolina The team at Commercial Sewing began the origins of Sur Last® by defining the requirements and testing of a new fabric that changed the industry for water repellency, UV longevity, anti-microbial finish and durability. In 1993, CSI collaborated with Glen Raven Technical Fabrics to develop the solution-dyed polyester fabric, Sur Last®, featuring new levels of durability and fade resistance. “CSI is always looking for better ways to do things, which is likewise a key part of Glen Raven culture,” says Kirk Fitzsimmons, Marine & Specialty Products Manager. “We’re tremendously excited about the opportunities that this partnership has created.” Glen Raven specializes in innovative solutions in the awning, marine, furniture, protective, military and geosynthetics markets.

Our dedicated team in Mexico specifically focuses on sewing and assembling our transportation covers, personal watercraft and motor covers for the marine and power sports customers. This team is focused on high volume production and allows for streamlined support to our west coast clients.

Our division in China was established in the early 1980’s and continues to grow and support our abilities to source materials, produce custom parts, and assemble high volume products that Commercial Sewing engineers have designed. The China team is consistently growing as we develop our portfolio of services to accommodate our customer production requests as well as maintain pricing efficiency.