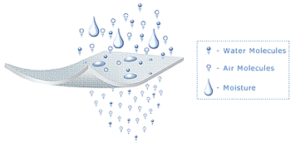

The ability of any fabric to transfer moisture is dependent on its ability to “wick” through the fabric. This is referred to as the Moisture Vapor Transfer Rate (MVTR) and is measured in Grams per Square Meter per 24 Hours (how many grams of moisture can pass through a square meter of fabric in a 24 hour period). This characteristic is a primary concern for clothing, especially outerwear. You may recognize Gore-Tex™ which is a well-known fabric containing this feature.

The ability of any fabric to transfer moisture is dependent on its ability to “wick” through the fabric. This is referred to as the Moisture Vapor Transfer Rate (MVTR) and is measured in Grams per Square Meter per 24 Hours (how many grams of moisture can pass through a square meter of fabric in a 24 hour period). This characteristic is a primary concern for clothing, especially outerwear. You may recognize Gore-Tex™ which is a well-known fabric containing this feature.

The outdoor environment is always seeking equilibrium, therefore, this “wicking” action allows moisture vapor to migrate in both directions. If conditions are conducive to a wet environment, the area underneath a cover will try and migrate to the outside and the reverse if the outside is the drier environment. Another example we can reference is the shift in temperature from evening to morning to afternoon. When the moisture content of the air from the evening is cooled, water beads can form on surfaces hence why we see water droplets on outdoor furniture in the early morning. It eventually dries as the temperature rises. This cycle can happen over and over under a boat cover is there is no way for the air to enter or escape; hence why we suggest properly cleaning and drying before a cover is placed or desiccant silica gel packets during periods of long storage.

Hydrostatic Water Resistance is measured in centimeters (cm). This indicates the pressure of water needed to penetrate a fabric. Heavy or wind-driven rain has a higher pressure than light rain. The test method is where a column is placed over the face of the fabric and filled with water until it begins to drip through the backside of the fabric. It is measured in centimeters and the higher the CM reading the higher the hydrostatic water resistance.

Conversely, fabrics with high MVTR’s have very low hydrostatic water resistance as they are opposing characteristics. Fabric with a hydrostatic head rating of 100 cm or less is regarded as shower resistant, with 150 cm usually being suitable for maintaining a dry condition. Pooling water will eventually seep through the fabric on low hydrostatic rated fabrics.

An absolute feature of a Mooring Cover is that it repels water and resists penetration so effectively that the boat interior doesn’t get wet during a rainstorm. The benefit of low MVTR’s is marginal at best and the highest Hydrostatic rate is more important to effectively protect the boat’s interior.

In summary, this is why we created our Balance Weave solution-dyed polyester fabric. It has the highest hydrostatic resistance of any other fabric so it will prevent water from penetrating our cover even under severe “pooling” conditions and lasts for 3-4 times longer than other fabrics.

Check out our official technical bulletin section for more facts and figures about our products.

![]()